Solutions by Industry

At the Sicelub Lubritech Group we have knowledge of production processes in the different industries where we have had a continuous presence for more than 30 years. This helps us to better understand the critical function of the different rotating equipment and, applying the concept that the best lubrication practices are closely related to the reliability of the equipment, we are able to make recommendations for improvement that add value to the supply chain. production. Our approach is entirely developed towards optimizing the Reliability and Availability of the equipment, in order to increase Production Efficiency. On the other hand, in these 30 years working in more than 10 countries, we have been able to find common patterns of improvement by industry, which allow us to be more assertive in the design of the solution.

Oil & Gas Downstream – Refineries and Chemical Plants

Refineries and Chemical Plants are continuous process industries with a large amount of critical rotating equipment. Since any decrease in reliability or availability can negatively affect Safety, the Environment, having serious impact in Production and increasing Maintenance Costs, good lubrication practices play a very important role in the Management of the Assets present there.

Refineries and Chemical Plants are continuous process industries with a large amount of critical rotating equipment. Since any decrease in reliability or availability can negatively affect Safety, the Environment, having serious impact in Production and increasing Maintenance Costs, good lubrication practices play a very important role in the Management of the Assets present there.

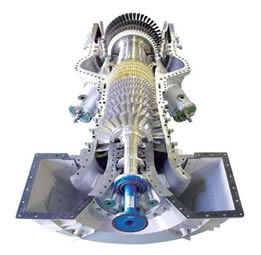

The technological applications of the Sicelub Lubritech Group in Refineries and Chemical Plants are very varied, since all equipment that can be lubricated has area of improvement. Undoubtedly, the most important equipment has to do with centrifugal pumps, especially those that operate with hot products and are plant-loaded; Turbomachinery used either to generate electricity, or to drive compression or pumping equipment, and cooling towers and fans in general for cooling water and products.

When initiating contact with a client, we first carry out a Tribological Audit to detect the areas of opportunity to generate more value, and based on it, an action plan is designed, which can range from a single intervention, to a continuous permanence to take on responsibilities as the Lubrication Department.

Some general guidelines that can be useful are:

- – Centrifugal pumps, small steam turbines, cooling towers: Undoubtedly, the most applied technology here is mist lubrication, which allows to extend the Mean Time Between Failures, automating lubrication.

- – Turbomachinery during Turnarounds: During start-up or commissioning and during Turnarounds, it is a mandatory requirement to perform a High Velocity Oleohydraulic Flushing; to remove internal dirt from the lubrication system, using turbulent flow, and reducing the time allocated for this process. The GSL has developed Flushing procedures that reduce the normal scheduled time for such intervention, using the recommendations of ASTM D-6439 and ASTM D-4378 standards.

- – Turbomachinery during Operation: Continuous purification of lubricants to remove water, particles, gases and varnishes. Constant attention with autonomous purification equipment that can be fixed, or portable for its management in different machines. Other actions to keep the lubricant free of contaminants, such as design and application of breather filters, improvement of filter elements, redesign of sampling ports, update of the lubrication system in accordance with API 614, among others.

- – PADELI approach: The GSL is capable of designing and applying a Senior Management Program in total Lubrication whose objective is to manage and operate the lubrication activities of a Refinery or Chemical Plant, including traditional lubrication, the certification of lubricators and the application of best practices to increase Tribological Reliability.

- – Lubricant Analysis Program: It is very important to design the Oil Analysis Program according to the criticality of the equipment to have the information that allows decision-making.

- – Lubrication Automation: We design and install grease automation systems to apply in Fans, Forced Drafts, etc.

- – Lubricant Storage: We design Lubricant Storage Stations (EDA’s)

Oil & Gas Upstream – On Shore y Off Shore

The production of gas and oil, whether on land or at sea is an extremely important activity in the Oil & Gas value chain. Also known by the acronym E&P; it involves various processes and technologies. The technological applications of Sicelub Lubritech Group in the E&P Industry are focused on maintaining reliable production equipment; paying special attention to those that do not have backup or stand-by equipment.

Some general applications.

- – FPSO’s and others during construction: commissioning phase, various activities of chemical cleaning and High Velocity Oil-hydraulic Flushing are required to intervene turbomachinery lubrication systems, hydraulic drive systems, among others. Our procedures contribute to significantly reduce intervention times.

- – Turbomachinery during Scheduled Turnaround: High Velocity Oil-hydraulic Flushing; to remove internal dirt from the lubrication system, using turbulent flow, and reducing the time allocated for this process.

- – Turbomachinery and hydraulic systems during Operation: Continuous purification of lubricants to remove water, particles, gases and varnishes. Constant attention with autonomous purification equipment that can be fixed, or portable for its management in different machines. It is vitally important to maintain the best levels of purification of this equipment on Offshore Platforms.

- – Centrifugal pumps: Application of mist lubrication with Lubrimate equipment.

Power Generation

LThe Power Generation Industry is of vital importance; either when it is in the Interconnected Network or when it is applied in specific industries for own generation or cogeneration. The Sicelub Lubritech Group operates mainly in Conventional Thermal Generation, Combined Cycle, Cogeneration, Nuclear, Hydroelectric and Wind. The main value we provide is to contribute to increasing Reliability and Availability of Production in rotating equipment, with a special focus on steam, gas, hydroelectric or wind turbines.

Some general applications.

- – Turbomachinery Turnaround: We carry out interventions for lubricant changes, filtration and High Velocity Oleohydraulic Flushing. In Gas Turbines, a special Flushing procedure may be required to remove Varnishes.

- – Turbomachinery during Operation: We have various technologies for the continuous purification of lubricants, removing contaminants such as water and particles, as well as varnish precursors. In each special case, we design the best application according to the data found.

- – Wind Turbines: In some countries we have special trailers to carry out lubricant changes and flushing in velocity multipliers. We also run filtrations to control cleaning code.

- – EHC Control Systems: We have a special application to optimize acidity control in EHC systems with phosphate diester oils, as well as the possibility of developing retrofits to change the type of lubricant.

The Pulp & Paper Industry has critical rotating equipment for plant production, such as paper machines and power generation turbines. A wide range of viscosities is used in plant.

Some general applications of the Sicelub Lubritech Group:

- – Power Generation Turbines: We provide High Velocity Oleohydraulic Flushing Services during Commissioning and Turnarounds; as well as continuous purification of lubricants to remove contaminants such as water, particles and varnishes.

- – Paper Machines: Both for their lubrication and hydraulic systems; High Velocity Oil-hydraulic Flushing are provided, Flushing to remove varnishes; and continuous purification of lubricants to remove contaminants such as water, particles and varnishes.

Iron & Steel Industry

The Steel Industry contains various processes and plants, oriented to the production of steel in various presentations. The action of the Sicelub Lubritech Group focuses on large rolling mill lubrication systems, power generation turbines; and hydraulic systems in general.

Some general applications.

- – Large lubrication tanks: We offer sale and continuous purification of lubricants to keep cleanliness levels low. In new installations orturnarounds, we perform High Velocity Oil Hydraulic Flushing Service and Chemical Cleaning to achieve fast and reliable starts.

- – Power generation turbines: We offer high-velocity oil-hydraulic flushing services during programmed start or stop and continuous purification of lubricants to remove water, gas particles and varnishes.

- – For critical applications: We offer mist lubrication to extend bearing life.

Mining

The Mining Industry is characterized by operating heavy mobile equipment and having process plants with Mills, Crushers, among other equipment. The care of the lubricant and the fuel is vital to ensure the Reliability of the Process.

Some general applications.

- – Large lubrication systems for mills and crushers: We perform high-velocity oil-hydraulic flushing services during commissioning phase and during Turnarounds. Objective of obtaining high standards of cleaning in the system, in the shortest possible time.

- – Mobile equipment, lubrication tanks in general: We carry out continuous lubricant purification to remove water, particles, gases and varnishes.

- – Fuel storage and supply system: We provide improvements in fuel filtration, during storage and dispatch.

CONTACT US

If you want further information about our products or services, do not hesitate to contact us.

Argentina

Lubritech Argentina SRL

Calle 80 N° 175 entre 116 y 117

Villa Elvira – La Plata – CP1900 – Buenos Aires – Argentina

Tel: +54 0221 4571457 / 4212232 / 4539725

España

Sicelub Ibérico SL

Calle Bratislava 65

30353 – Cartagena – Murcia – España

Tel: (+34) 968 541 042

Cel: (+34) 618 730 333 (sólo temas comerciales).

Venezuela

Lubritech Venezuela

Brasil

Lubritech do Brasil

Alameda Plutão, 235

American Park Empresarial NR – Indaiatuba – São Paulo

Brasil – CEP 13347-656

Cel: + 55 (19) 3825-3669

Italia

Sicelub Italia

Colombia

Sicelub Colombia Ltda

México

Sistemas Centrales de Lubricación

Patriotismo 359

Ciudad de México – 03800 – México

Oficina: + (52) 55 5528 5014

Móvil: + (52) 55 3232 1991

Móvil: + (52) 55 3988 4202

Perú

Lubritech Perú

Av. Dionisio Derteano 184 Of. 603

San Isidro, Lima Perú.

Contacto: +51997519459 / +5492214854670.

Trinidad & Tobago

Lubritech Caribbean