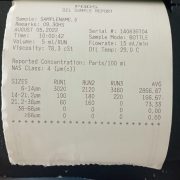

Lubritech do Brasil has just completed the first stage of Turnaround Service in a big lubricating system (more than 12,000 Gallons of Oil) of a Turbo Compressor in a Chemical Plant in Brazil. We were there working more than 15 days, and we drained the oil, performed cleaning in oil reservoir, filter and fill the new charge. We reached a NAS 4 for cleanliness!

For this job, we utilized a filtration unit of 150 GPM, with two filter elements of 34” large and an Oil Purifier for removing water.

Second stage of the job, it would be focused on decreasing varnish potential in the system. For this, we will use a liquid product for improving solvency, and a Balance Charge Agglomeration Technology for removing varnish. ISOPur.

Technicians working in that Project were:

Marcos Santos, Edmilson Oliveira, Djalma Alves, Manuel Santos, Alexandre Adão Lopes and the external support of Edson Zillig in logistic.

You can see some pictures of the job.