During April, May and June, we have performed several services in our Brazilian Company, Lubritech do Brasil. The market has been asking for more services, and our team has been working in a hard way, in order to deliver. We have also counted with the support of our colleagues from Lubritech Perú, and Lubritech Argentina.

Main services we have performed are:

- High efficiency Filtration Service in 9 Gas and Steam Turbine, in a big Power Plant. We have filtered around of 45,000 Gallons of Oil in 30 days, using 40 GPM filtration skids until achieving ISO Code 17/15/12.

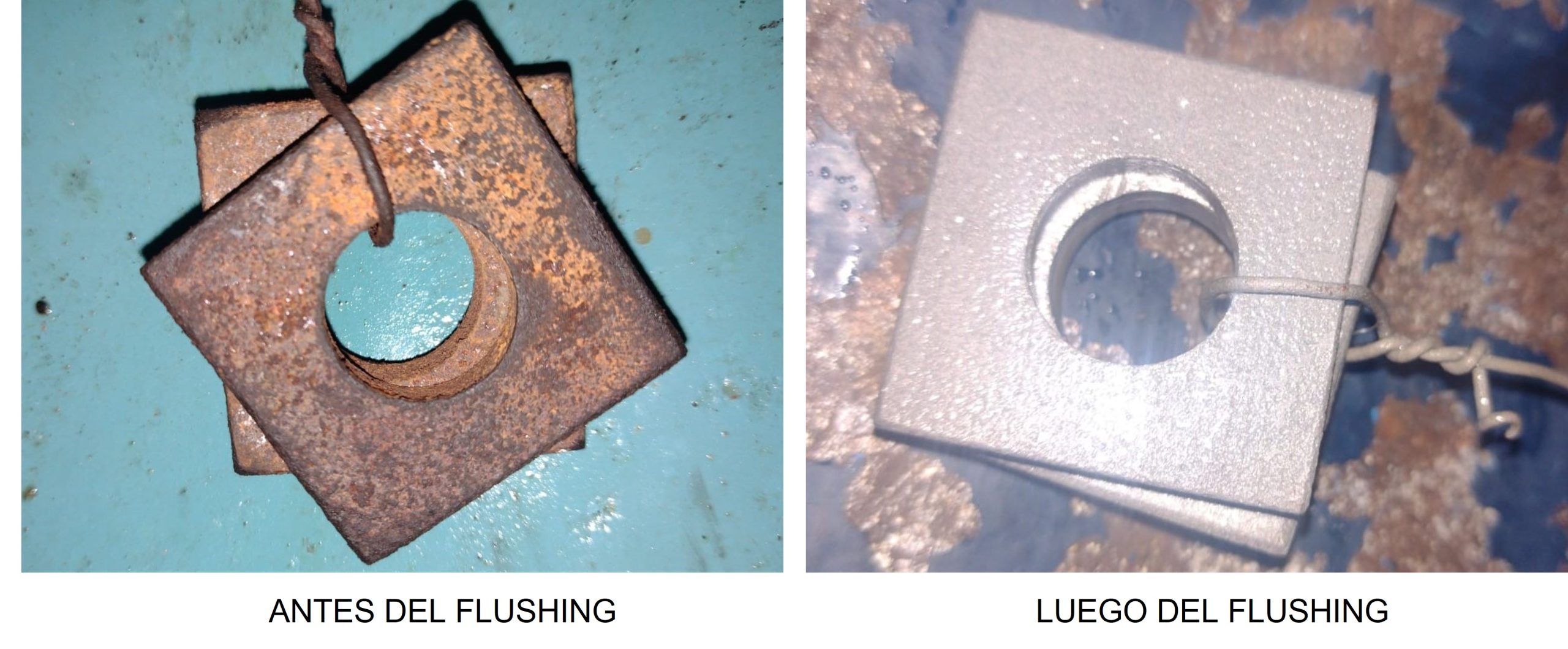

- High Velocity Oil Flushing in 2 reciprocating and centrifugal compressors in an important Refinery of Sao Paulo State. We have used equipment of 500 GPM achieving the highest standards of quality.

- High Velocity Oil Flushing Service in a Gas Compressor and Centrifugal Pumps in an Off-Shore Platform. Even the logistic was a challenge, we were able to do a great job!

We would like to thank to our Customer and our team for their commitment. We share some pictures, and if you want to have additional information, please reach us at www.sicelub.com; send an email to info@sicelub.com; or write a WhatsApp message to +34 616 54 70 86.