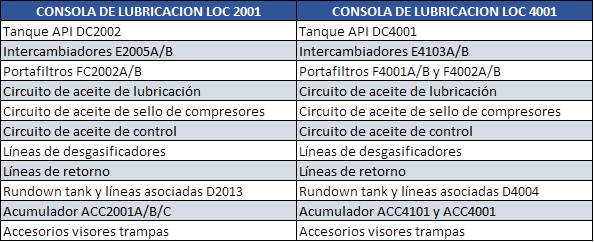

January is usually a summer holyday month in Argentina and Brazil. In our Company, we have been working in both countries, and we want to share with you our news!

In Brazil, we performed a very important job in a big chemical plant in north of the country. The job was High Velocity Oil Flushing to an Alstom Turbo Generator. We performed cleaning in lubricating, control and jacking systems. Total of lubricant oil is 3,500 Gallons and for the service we used a 2,200 GPM unit, and Thermojet Oil Purifier.

We prepared and Engineering for bypasses and we were able to complete the scope before lead time. Our services were leaded by Alexandre Adao with other 3 lubrication technicians.

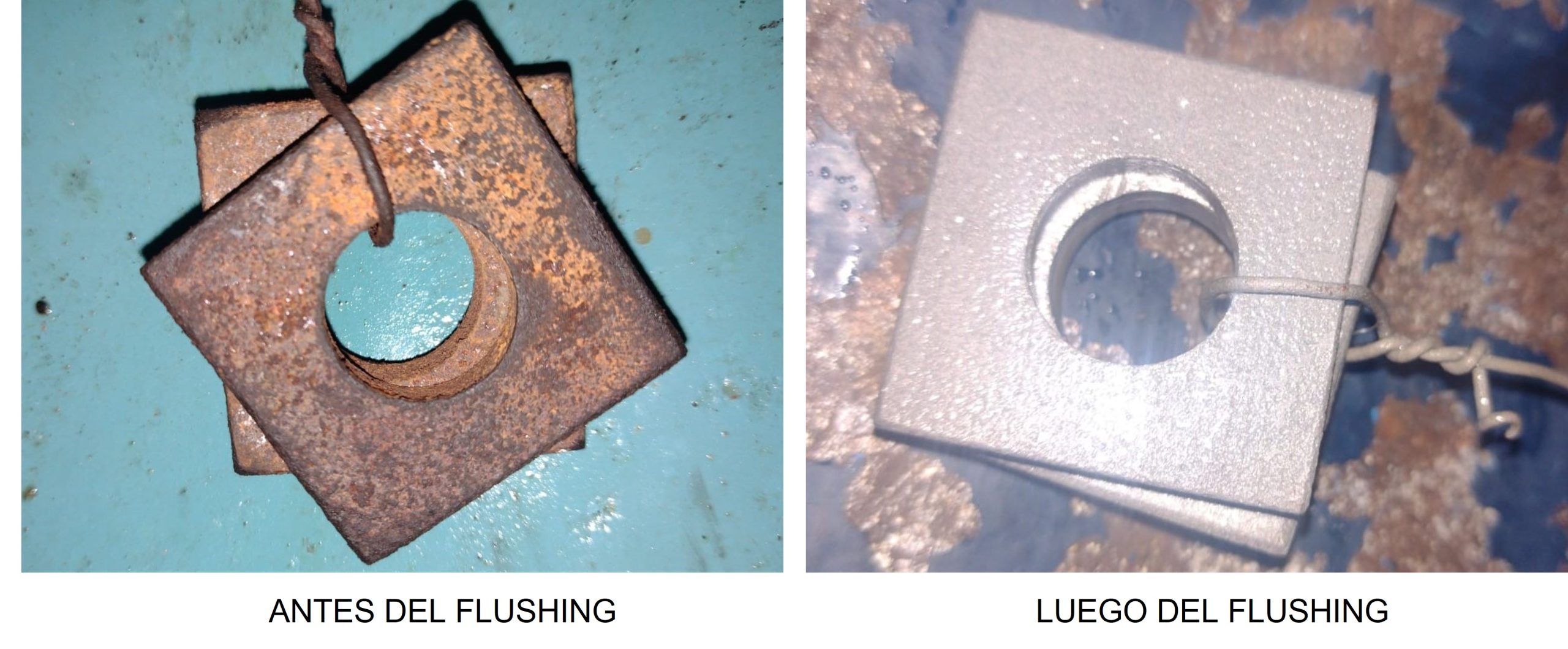

In the case of Argentina, we were performing the service in a Steel Mill Plant, where we performed Chemical Cleaning and High Velocity Flushing Services. We finished the job in the scheduled time. You can see a picture of “before” and “after” the cleaning.

We would like to thank to our Customer and our team for their commitment. We share some pictures, and if you want to have additional information, please reach us at www.sicelub.com; send an email to info@sicelub.com; or write a WhatsApp message to +34 616 54 70 86.